Dead Batteries Deserve a Second Life

Batteries should be recycled, so the valuable minerals therein—including cobalt and lithium—can stay in the economy.

Batteries have proven to be an integral part of people’s day to day life.

And if you use a digital camera, smart phone, or drive an electric car, you rely on a specific type of battery: lithium-ion. Our need for these batteries won’t be ending soon, with estimates suggesting the lithium-ion battery market will reach USD 77 billion by 2024.

But what happens to your lithium-ion battery once it dies?

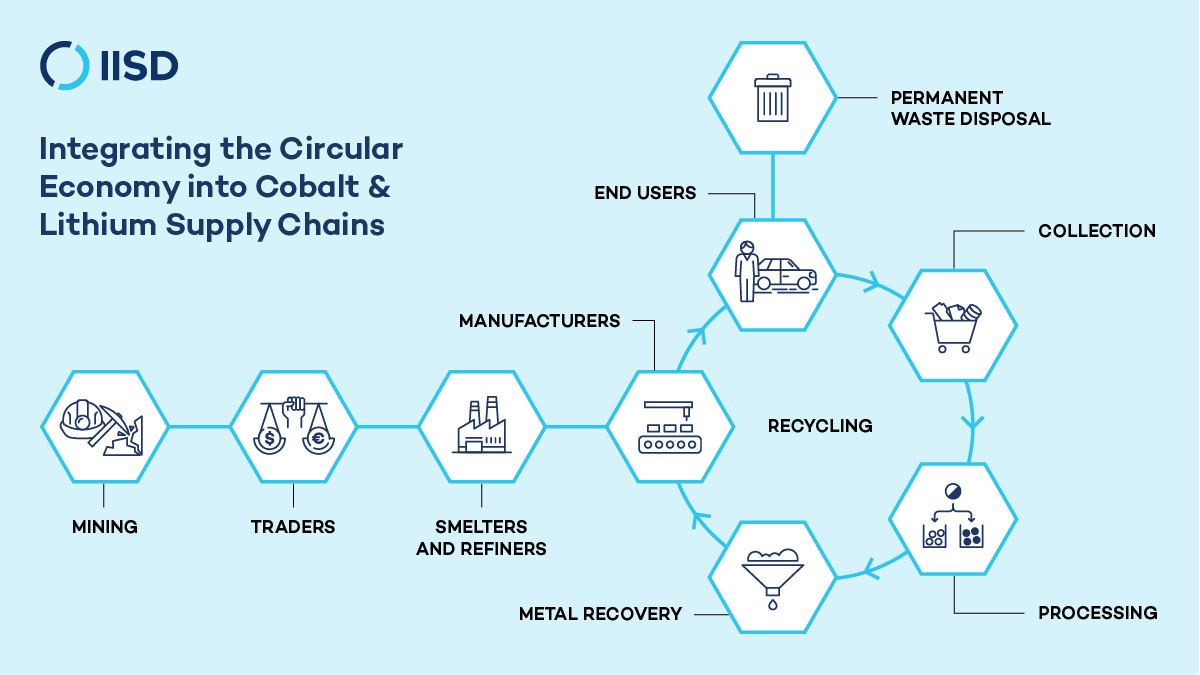

The battery should be recycled, so the valuable minerals therein—including cobalt and lithium—can become part of the circular economy.

The circular economy is a process of minimizing waste and making the most out of finite resources to achieve sustainable development. Many governments and mining companies are seeing the value of mineral recycling, including the U.S. Department of Energy, which recently announced its USD 20.5 million investment in lithium battery recycling.

However, there are barriers to effective mineral recycling. Below are just a few, but you can read a more comprehensive list in our new report, Sustainability and Second Life: The case for cobalt and lithium recycling.

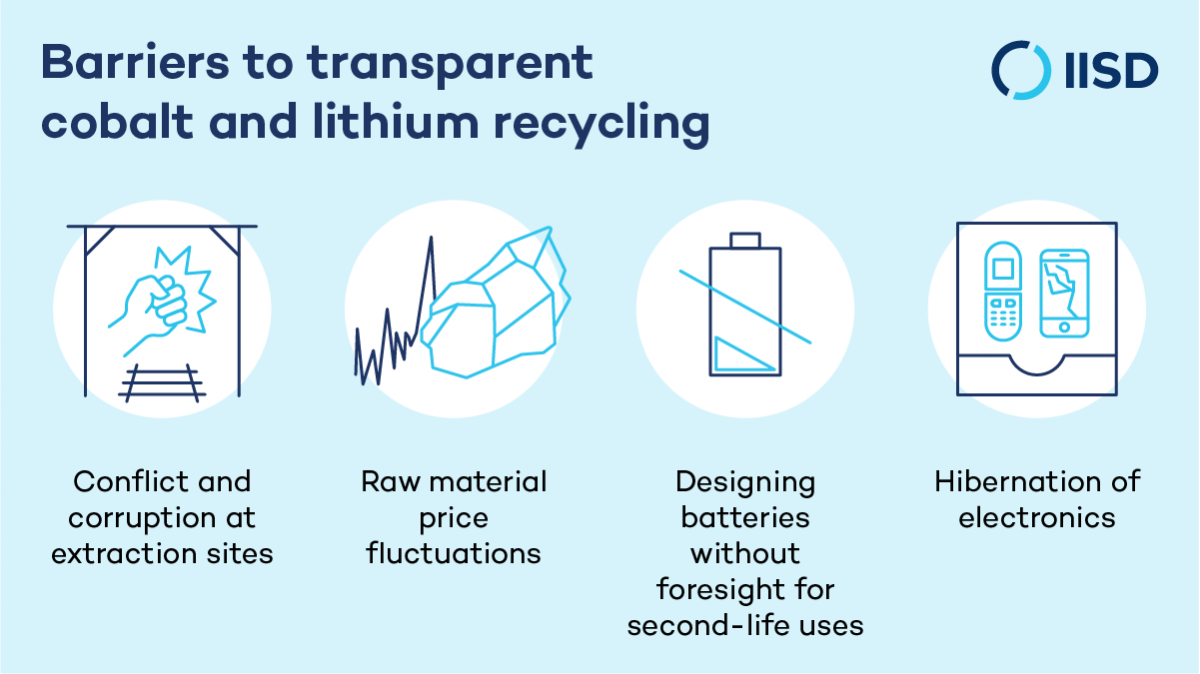

Conflict and corruption at extraction sites

Certain minerals, such as cobalt and lithium, are extracted from regions where fragility, conflict and violence are prevalent. Some stakeholders hesitate to recycle materials that originated from conflict zones, as they worry that will compound their complicity in the corruption and violence intrinsic in their origin.

Raw material price fluctuations

Prices for virgin lithium and cobalt are projected to increase as the demand for batteries grow, especially driven by the uptake of electric vehicles (EVs). This increase in price can lead manufacturers to substitute cobalt with other, low-value materials, making batteries not economically worthwhile to recycle.

Designing batteries without foresight for second-life uses

The design of products can limit the ability of minerals to be recovered and recycled. If they are manufactured with permanent assembly methods, for example, this presents a challenge to proper disassembly and dismantling in secondary processes. And without proper labelling, the lithium-ion batteries would need to be tested and assessed before designating them for reuse, remanufacturing or recycling. This process which could be time consuming, energy intensive and expensive.

Hibernation of electronics

Hibernating electronics, the period when the product isn’t thrown away but held onto despite a lack of use by the owner, is a major obstacle, because while these items typically retain most of their battery capacity, they do not enter processes for reuse, remanufacture or recycling.

Challenges can also appear after a product has reached its end of life in the recycling supply chain. Inefficient collection infrastructure, technological and safety concerns, and transparency issues can also present an obstacle to lithium and cobalt recycling. And even if these barriers are addressed, there remain a number of issues in the regulatory environment impede increased mineral recycling. These barriers include the public sector’s struggles to establish appropriate definitions for secondary processes, to clearly allocate responsibility and liability in the supply chain for recycled products, and to set meaningful recycling targets.

With all these barriers to lithium and cobalt recycling, how can stakeholders improve and expand upon mineral recycling so that it can contribute to a circular economy and sustainable development?

Increased collaboration between stakeholders

The public sector, private actors and civil society should collaborate to overcome market and regulatory barriers. This coordination will ensure that new or revised investments and regulations are reflective of the changing needs of the recycling industry.

The public sector should also coordinate their efforts with relevant stakeholders to develop and understand applicable definitions of recycling and other secondary processes, clearly designate the actors responsible and liable for recycling materials, communicate these regulations to businesses, and evaluate the risks and benefits of mineral recycling using multiple values.

Fostering eco-designs

Manufacturers should consider the eventual recycling of the product during its initial design to ease the dismantling, recovery and retrieval phases to include recycled lithium and cobalt in the circular economy.

Encouraging recycling among consumers

Awareness of mineral recycling processes should be raised among consumers, and incentives should be applied to encourage consumers to recycle their unused electronics. For example, a financial incentive can be offered to consumers for handing in their used mobile phones, laptops and other electronics.

Additional opportunities to foster mineral recycling include: enhancing transparency in the supply chain, developing new business models for mineral disposal, improving the perception of products with second-life minerals, and evaluating the risks and benefits of mineral recycling using multiple values.

As some of the main components in lithium-ion batteries, lithium and cobalt will play central roles in the transition to a low-carbon economy. When the public sector, private actors and civil society work together to ensure transparent mineral recycling processes, a sustainable circular economy can be achieved.

You might also be interested in

Securing India's Copper Supply

This policy brief emphasizes the need for India to develop a comprehensive copper strategy.

Avoiding Trade Concerns in the Design of Plastic Pollution Measures

IISD provides insights on aspects of WTO members' plastics that have created friction with trading partners and suggests recommendations for the adoption of such policies in the future.

Watts in Store Part 2

Creating an enabling environment for grid battery deployment in South Africa while maximizing key benefits and minimizing social and environmental risks.

A Balancing Act

With Nigeria's growing population in need of wide-ranging solutions to the multidimensional poverty it faces, a new IISD report outlines how the LNG dash could ultimately leave the economy more vulnerable to external shocks and without a solid domestic foundation.